Design of a Primitive Nanofactory

Journal

of Evolution and Technology -

Vol. 13 - October

2003 -

PDF Version PDF Version

http://jetpress.org/volume13/Nanofactory.htm

Chris Phoenix

Director of Research, Center for Responsible Nanotechnology http://CRNano.org

Abstract:

Molecular manufacturing requires more than mechanochemistry. A

single nanoscale fabricator cannot build macro-scale products. This

paper describes the mechanisms, structures, and processes of a prototypical

macro-scale, programmable nanofactory composed of many small fabricators.

Power requirements, control of mechanochemistry, reliability in the face

of radiation damage, convergent assembly processes and joint mechanisms,

and product design are discussed in detail, establishing that the design

should be capable of duplicating itself. Nanofactory parameters are

derived from plausible fabricator parameters. The pre-design of a

nanofactory and many products appears to be within today's capabilities.

Bootstrapping issues are discussed briefly, indicating that nanofactory

development might occur quite soon after fabricator development.

Given an assembler, a nanofactory appears feasible and worthwhile, and

should be accounted for in assembler policy discussions.

Contents:

1. Introduction

2. Background

2.1. Mechanochemistry

2.2. Mechanochemical fabricator

designs

2.3. Parts assembly, scaling,

and product integration

2.4. Nanofactory overview

3. Components and Innovations

3.1. A Thermodynamically Efficient

Stepping Drive

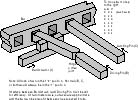

Figure 1:

Pin Drive

3.2. Joining Product Blocks

3.2.1.

The Expanding Ridge Joint

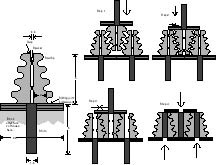

Figure

2: Expanding Ridge Joint

3.2.2.

Functional joints

4. Nanofactory Architecture

4.1. Mechanochemical functionality

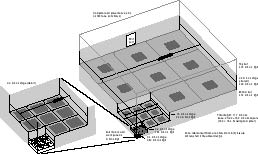

Figure 3:

Workstation Grids

4.2. The reliable basic production

module

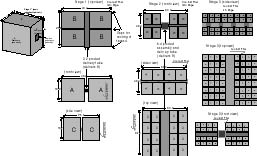

Figure 4:

Production Module

4.3. Gathering stages

Figure 5:

Convergent Assembly Fractal Stages

4.4. Casing and final assembly

stage

Figure 6:

Nanofactory Layout

4.5. Issues in bootstrapping

4.6. Improving the design

5. Product design

5.1. Levels of design

5.1.1.

Nanoparts

5.1.2.

Nanomachines

5.1.3.

Nanoblocks

5.1.4.

Patterns and Regions

5.1.5.

Folds

5.1.6.

Networks

5.2. Simulation and testing

5.2.1.

Design and simulation

5.2.2.

Testing and debugging a nanofactory-built product

6. Control of the nanofactory

6.1. Nanocomputer architecture

and requirements

6.2. Placing the nanoblocks

6.3. Specifying the nanoblocks

7. Product Performance

7.1. Strength, stiffness, and

shape

7.2. Appearance

7.3. Complexity

7.4. Design

7.5. Powering the product

7.6. Computation

8. Nanofactory calculations

8.1. File size and data distribution

8.2. Fabricator control, energy,

and cooling

8.3. Physical arrangement and

mass

8.4. Product cycle, duplication,

and bootstrapping time

8.5. Radiation and failure

8.6. Cost and difficulty of

manufacture

9. Conclusion and discussion

Appendix A. Calculations in software

Appendix B. Projections from the Merkle assembler

B.1. Mechanochemical baseline

B.2. Chemistry, electronics,

and mechanics

B.3. Mechanochemical error rate

References

1. Introduction

The utility of a new technology depends on many factors, including the

difficulty of development and the ease and cost of use. Most technologies

require significant additional work to form useful products. Previous

theoretical work in molecular nanotechnology has provided only incomplete

and fragmentary answers to the question of how molecular nanotechnologic

devices can be used in practice. Although it appears that fabrication

systems can be built on a nanometer scale (Drexler, 1992), small devices

will be difficult to use directly in many applications. Several designs

have been proposed in more or less detail (Drexler, 1986, 1992; Bishop,

1996; Merkle, 1997a; Hall, 1999; Freitas and Merkle, in press) for parallel

control of many small fabricators to make a large product. Other

proposals (Hall, 1993) combine many small products to create a large product.

However, each of these proposals has provided insufficient detail to allow

estimation of their practical difficulty and utility.

This paper builds on previous proposals to describe an architecture

for combining large numbers of programmable mechanochemical fabricators

into a manufacturing system, or nanofactory, capable of producing

a wide range of human-scale products. The proposed system is described

in sufficient detail to allow estimation of nanofactory mass, volume, power

requirements, reliability, fabrication time, and product capability and

cost, as simple functions of the properties of the mechanochemical fabricator

component. Bootstrapping a human-scale system from a sub-micron system

is also discussed. Discussion of product design issues and nanofactory

manufacturing capability demonstrates that the nanofactory should be able

to efficiently fabricate duplicates of itself as well as larger versions.

This proposal differs from previous proposals in that, with the exception

of mechanochemical component fabrication, design of the nanofactory should

be within the reach of present-day engineering; physical structures and

functional requirements are described in sufficient detail that remaining

problems should be within the capability of current engineering practice

to solve. In particular, the design considers all transport and manipulation

requirements for raw materials and product components, as well as control,

power, and cooling issues.

This exploration can provide a basis for estimating the practical value

and difficulty of developing a nanofactory. As noted in (Merkle,

1999), even a primitive sub-micron mechanochemical fabricator may produce

valuable products. The question at hand is whether, once such a device

is developed, it is feasible and worthwhile to adapt such devices into

a nanofactory. Since no complete designs, or even complete parameter

sets, exist for a mechanochemical fabricator, this question cannot be answered

fully at this time. However, the results of the present paper can

be applied to a wide range of hypothetical fabricator parameters.

As fabricator designs are proposed in increasing detail, these results

will become increasingly useful in predicting the capabilities of a nanofactory

based on such designs. Issues of product design and manufacture are

examined in order to establish that the nanofactory is capable of fabricating

duplicates and larger versions of itself. The time required to bootstrap

a human-scale factory from a nano-scale fabricator cannot be estimated

with any certainty, since bootstrapping will require time for debugging

and redesign as well as for fabrication of larger versions. However,

the minimum time required for fabrication can be estimated, and the design

developed here is simple enough that debugging and redesign may be fairly

simple and rapid.

The paper is arranged in several sections. Section 2

surveys previous work toward manufacturing systems relying on mechanochemistry

and producing human-scale products. Section 3 describes

two innovations required for efficient operation of the nanofactory architecture.

Section 4 describes the nanofactory architecture, including

a highly reliable

production module incorporating several thousand

mechanochemical fabricators and a scalable convergent assembly and transport

architecture for integrating large numbers of production modules.

Section 5 covers issues of product design to establish

that the nanofactory is designable and buildable by itself. Section

6

discusses computer control of the nanofactory. Section 7

covers product performance. Section 8 provides

calculations relating nanofactory performance and characteristics to fabricator

performance and characteristics. Section 9 summarizes

the paper. Appendix A is a computer program that

implements repetitive calculations for probability, size of components,

and pressure in cooling channels. Appendix B is

a brief discussion of the suitability of a proposed fabricator design (Merkle,

1999) for the nanofactory architecture.

2. Background

In order to create useful products with molecular manufacturing, several

steps are required. Large products cannot be built by a single small

fabricator. Even at a million atoms per second, building a gram of

product would take more than a billion years. Building a large product

requires a system implementing several steps. First, molecules must

be reacted under positional control by fabricators to form parts.

Second, the parts must be combined into nanosystems. Third, the nanosystems

must be combined into products, either by physical attachment or by distributed

control. Many authors have considered one or more of these steps,

but none has described a complete factory system.

2.1. Mechanochemistry

As used in this paper, mechanochemistry refers to the process of inducing

covalent bond formation or breaking under controlled conditions by mechanical

motion. As discussed in (Drexler, 1992, chap. 8 & 9), mechanochemistry

performed in a well-controlled environment appears sufficient to fabricate

small devices from covalently bonded carbon (diamondoid). Merkle

(1997d, 1998) describes additional reactions that could be used to build

diamondoid products--a complete hydrocarbon "metabolism" capable of refreshing

the molecular deposition tools, and Merkle and Freitas (2003) have analyzed

a specific diamond mechanosynthesis tool in detail.. The present

design assumes that some such chemistry is possible in practice, and will

have been characterized to some extent in the process of building a working

fabricator. Diamondoid fabrication chemistry need not be completely

understood--a basic set of a few reliable deposition reactions, with motions

parameterized to account for edges and other discontinuities, should be

sufficient to build bulk diamond.

In order to focus on nanofactory architecture, the present work does

not consider mechanochemical operations in detail. Instead, the design

assumes the existence of a small programmable mechanochemical fabricator.

To simplify architectural considerations, the fabricator is assumed to

be self-contained: it must be capable within a small volume of performing

all mechanical motions necessary to fabricate parts from feedstock and

assemble them into small devices of complexity comparable to itself.

2.2. Mechanochemical fabricator designs

Several proposed devices appear to be capable of performing reliable mechanochemical

operations with sufficient flexibility for self-duplication. These

include the robot arm described by Drexler (1992, sec. 13.4), the double

tripod described by Merkle (1997c), the molecular mill described by Drexler

(1992, sec. 13.3), and the "parts synthesizer" described by Hall (1999).

Additionally, biological or hybrid systems have been proposed (Bradbury,

2003) in which organic synthesis is used to build relatively large chemical

components. Each of these systems is attractive for various reasons.

The robot arm requires several different mechanical components, including

small gears, triply-threaded toroidal worm drives, and several types of

cylindrical sliding interfaces. Each of these components may require

significant atom-level design. In addition, the robot arm requires

a control system involving rotational motion on several drive rods.

Nanometer-scale clutches have not been designed in detail. In order

to provide results relevant to early fabricator and nanofactory development,

this paper does not assume that devices of such complexity can be built.

Hall's parts synthesizer requires separate assembly robots to deliver chemicals,

and the power/control mechanism is not specified.

Systems relying on many biologically-based feedstock molecules require

separate synthesis and assembly areas, which may have quite different environmental

requirements. In addition, they may require nontrivial transport

mechanisms to prevent premature reaction of the feedstock molecules.

Finally, such systems do not appear to permit the fabrication of diamondoid

structures.

The molecular mill is an attractive concept for several reasons.

It does not require explicit control of each mechanochemical operation,

thus greatly increasing efficiency over the other three proposals.

Operations can also be quite fast, since merely moving a belt a short distance

is sufficient to accomplish a mechanochemical operation. However,

each reactive encounter mechanism, or station, in a molecular mill performs

only one mechanochemical operation. Although each station is efficient,

in the sense of processing a mass equal to its own in a short time and

with little energy wasted, a large number of stations would be required

to fabricate all the parts needed to build a nanofactory, let alone the

desired range of products. This number has not been quantified.

Additional design would be required to explain how a number of stations

performing different mechanochemical operations and using different parts

can produce all the required parts for self-replication given that only

one chemical operation is performed at each station. Although this

does not contradict the possibility of a self-replicating set of mills,

it indicates that the set may be large and difficult to design. In

addition, the set may grow unpredictably when required to produce additional

parts for the non-fabricator portions of the nanofactory, and may need

significant modification if the design of a part must be changed.

Accordingly, a mill solution is not used in this paper. However,

it should be noted that a combination of a mill making small blocks and

a double tripod capable of both joining blocks seamlessly (Drexler, 1992,

sec. 9.7.3) and performing detailed mechanochemistry may be fast, flexible,

and relatively easy to design, and would be preferable to the simple robotic

manipulator implicitly assumed for this baseline design.

The current design effort is based loosely on a double-tripod "assembler"

discussed by Merkle (1999). Merkle's assembler is self-contained,

simple to control, and approximately the right size for a basic factory

or product building block. Every effort has been made to avoid depending

on any specific property of Merkle's design. However, the claimed

feasibility of this design serves as inspiration for the present effort

to integrate designs with comparable functionality into a monolithic nanofactory.

2.3. Parts assembly, scaling, and product integration

Several nanotech manufacturing designs have been proposed that could be

used to build large products. For example, Bishop (1996) describes

an "Overtool" composed of multiple "active cells" and "gantry cells" which

can both do mechanochemistry and encompass and manipulate a large product.

This design is incomplete, lacking description of control algorithms and

internal communications. Hall (1999) describes a system of robots

and framework components that can in theory scale to large size and then

make large products. However, feedstock delivery and system control

are not specified, and products it can fabricate are not described.

Drexler (1992, chap. 14) describes a system in a fair amount of detail,

including estimates of volume, mass, and replication time. However,

this description does not include the assembly operations used, robotics

required, or control of those robotics. Additionally, the system

uses molecular mills, which have not been studied in detail, and the physical

layout of the system is specified only in general terms. This work,

though seminal and inspiring, does not permit detailed estimation of the

technological sophistication required to design such a system. Merkle

(1997a) described a variant of that system, including fabrication time

and the suggestion of assembling products from large sub-blocks.

However, he did not calculate the power requirements, describe the internal

control mechanisms, or discuss product design issues or the feasibility

of self-replication in any detail.

Large-scale cooperative designs are not well understood today, and directing

them may be expected to be difficult. Hall (1993) describes a "utility

fog" composed of many small identical robots. Such a system would

be relatively simple to manufacture, requiring no large-scale assembly.

Hall suggests that the fog could use any of several fairly simple algorithms

to simulate solid objects. However, he also does not consider how

to power the product/object, and the control algorithms are not worked

out in detail. Also, his fog is quite weak for its mass, at least

compared to a more strongly fastened diamondoid product.

The purpose of the nanofactory is to build strong, functionally rich,

monolithic, human-scale products that are easy to design and use.

Several innovations described in this paper allow a nanofactory design

to be presented in detail for the first time. The nanofactory itself

is intended to be in the set of possible products. The paper focuses

on early development and on demonstrably feasible designs, so does not

include some obvious but currently speculative techniques for improving

performance. The design is deliberately simple, especially in minimizing

the amount of mechanochemical design needed in addition to the preexisting

fabricator. The major design effort focuses on mechanical and digital

design, physical layout, and fault tolerance.

Mechanical design methodology has achieved great competence in the transformation

of mechanical motion and force. Many devices have been developed

to accomplish this, such as cams and followers, rack and pinion drives,

planetary and differential gears, and pantographs. Drexler (1992,

chap. 10) demonstrated that many of these devices can be translated directly

to nanometer scale. However, many of Drexler's designs use a specialized

arrangement of surface atoms, and sometimes of internal atoms. Such

devices would require individual chemical design. To avoid the unknown

but potentially large effort involved in developing new chemical synthesis

for new mechanical structures, the present design does not generally assume

the use of mechanical features smaller than ~1 nm. Such a design

is referred to as "bulk diamond", meaning that simply specifying a suitable

volumetric design to be filled with diamond lattice is sufficient to specify

a part with the required mechanical function.

Although a wide range of sensing and feedback technologies have been

developed at the macro scale, some of them do not work at the nanometer

scale (e.g. optics and electromagnets; see Drexler, 1992, sec. 2.4), and

others may require excessive volume or complexity. In general, this

design effort avoids sensing in favor of predictability and reliability.

Digital logic is useful for performing repetitive functions, doing precise

calculations, and selecting among alternatives using well-specified criteria.

Software systems that interact with mechanical systems may be hampered

by sensor data that are not well specified. Accordingly, this design

does not make much use of feedback, or require software to deal with "fuzzy"

situations. Almost all aspects of nanofactory operation are deterministic;

this mirrors the (theoretically) deterministic nature of the mechanochemical

technique (Drexler, 1992, sec. 6.3). Because the factory layout is

extremely repetitive and strictly hierarchical, issues in controlling a

large number of fabricators and robots can be reduced to controlling a

single fabricator or robot, plus simple iteration.

As previously noted, this paper builds on work which demonstrates that

a nanofactory is conceptually feasible. The design presented here

is sufficiently detailed that the feasibility of each part of it can be

assessed. However, it is sufficiently general that it can accommodate

a variety of mechanochemical systems. Where design principles are

well understood, details are not supplied. For example, the use of

a gantry crane is specified in order to demonstrate the existence of robotics

capable of doing the job required, and to allow approximate calculation

of the mass of those components. The drive mechanism of the gantry

crane is not specified; however, given a design tolerance of 1 nm and the

presumed feasibility of motors as small as 50 nm in diameter (see

Section 8.2), it is clear that such a mechanism can

be designed in a wide range of sizes; at the present level of design, it

is not necessary to examine work on industrial robotics.

The extreme conservatism that is appropriate for a feasibility demonstration

is less appropriate for a preliminary engineering study. For example,

it is conservative to assume that each individual part will require individual

design at the atomic scale. However, it is reasonable to assume that

in the case of a rod with bumps regularly spaced on it, the rod can be

extended and bumps can be added or removed without requiring detailed redesign.

Thus the use of mechanical digital logic designs (Drexler, 1992, chap.

12) is assumed to require a mechanochemical design effort for only a fixed

and relatively small number of parts. Likewise, the quantitative

sections of this paper choose typical or reasonable values instead of extreme

or pessimistic values.

2.4. Nanofactory overview

The nanofactory system described here incorporates a large number of fabricators

under computer control. In a single product cycle, each fabricator

produces one nanoblock, approximately the same size as the fabricator.

The blocks are then joined together, eight sub-blocks making one block

twice as big. This process is repeated until eight large blocks are

produced, and finally joined in an arrangement that is not necessarily

cubical. The output of multiple product cycles may be combined to

produce large products. The production system is arranged in a three-dimensional

hierarchical branching structure (see Section 4.3)

which allows the sub-block assembly to be done by machinery of appropriate

size. Eight factories of a given size can be combined to form one

larger factory; the 64 blocks produced are joined into eight blocks twice

as big. The design is easily scalable to tabletop size, with a ~1

meter factory producing eight ~5 cm blocks per product cycle. As

discussed in Section 8.4, depending on the capabilities

of the mechanochemical fabricator, the time required for a product cycle

will be conveniently measured in hours. The blocks need not be solid

cubes, and their interior may be quite complex. As discussed in Section

5.1.5,

products can be unfolded after manufacture, greatly increasing the range

of possible product structures and allowing products to be much larger

than the nanofactory that produced them.

The exact size of the nanoblock is unimportant. For this design,

a 200-nm cube is convenient: it is large enough to contain a simple 8086-equivalent

CPU, a microwatt worth of electrostatic motors/generators, a shaft carrying

0.4 watts (Freitas, 1999, sec.

6.4.3.4), or the Merkle assembler (1999), but small enough to be fabricated

quickly and to survive background radiation for a useful period of time.

As discussed in Section 6, the partitioning of the product

into nanoblocks, and the use of relatively large sub-blocks at each step,

allows the use of relatively simple robotics and control algorithms in

the nanofactory. As discussed in Section

5, such

division also simplifies product design without imposing many practical

limits on product complexity. (W. Ware points out that a combination

of tetrahedra and truncated tetrahedra is also space-filling, and that

this may be more compatible with the tetrahedral diamond matrix.)

At the smallest scale, the organization of the factory changes to allow

simpler distribution of feedstock, cooling, power, and control, and simpler

error handling. A production module consists of one computer

and a few thousand fabricators. It produces a few blocks, a few microns

in size, by combining a few thousand nanoblocks. These rectilinear

production modules incorporate a few block assembly stages. They

are combined into the smallest factories, which are also rectilinear--and

so on to any size desired. At each stage, product blocks are delivered

through the center of the smallest face, allowing compact stacking of multiple

modules or stages. The stages are stacked on either side of a gathering/assembly

tube which contains simple robotics to join the incoming product blocks

into larger blocks and deliver them out the end of the tube. Two

stacks of stages, plus the tube in between, constitute the next higher

level stage.

The nanofactory design is highly repetitive: each input (sub-factory,

or substage) to a stage is identical. Thus only one design is required

for each level, regardless of the number of substages at that level.

Since each stage joins eight blocks to form one block with twice the linear

dimension, 19 sizes of stage (4 internal to the production module) are

required to progress from a 200-nm nanoblock to a 10.5-cm product.

(One additional stage, a simplified gathering stage, is used to transition

from production modules to gathering/assembly stages.) Most of these

stages perform identical block-joining operations. The design of

one stage may be used with minor modification for several similar stage

sizes.

A nanofactory built with primitive fabricators and control systems may

use a lot of power. It will be cooled by a fluid with suspended encapsulated

ice particles (Drexler, 1992, sec. 11.5). Thus the temperature of

the nanofactory will be a uniform 0 C (273 K). This is significant

for the energy used by digital logic (Section 8.2)

and for aligning and joining large blocks (Section 3.2.1).

The control architecture of the nanofactory, like the physical arrangement,

is strictly hierarchical. Instructions can be distributed from central

computers directly to the computers that directly control the fabricators.

All error detection and correction takes place either within a single nanocomputer

or within a production module controlled by a single nanocomputer, and

error reporting and compensation are not required beyond the production

module. There is no need for communication between any two computers

at the same level; a simple tree architecture can be used to send all required

data (Section 8.1). Exotic or complex control

algorithms, networking architectures, and operating systems are not required.

The size, mass, energy requirement, and duplication time of this nanofactory

design depend heavily on the properties of the fabricator. Sections

8.2,

8.3,

and 8.4 quantify these relations. With the assumptions

made in those sections, a tabletop nanofactory (1x1x1/2 meters) might weigh

10 kg or less, produce 4 kg of diamondoid (~10.5 cm cube) in 3 hours, and

require as little as fifteen hours to produce a duplicate nanofactory.

3. Components and Innovations

To provide a workable design for a simple first-generation nanofactory

made from primitive fabricators, several innovations are described.

The linear ratchet drive proposed by Drexler (1992, sec. 16.3.2) is extremely

inefficient. Section 3.1 describes a thermodynamically

efficient stepping drive that is applicable to all stepping actuators.

The problem of how to join small components into a large product has been

greatly simplified by designing a mechanical fastening system, described

in Section 3.2.1. It has only two moving parts,

requires no insertion force or actuation, preserves much of the strength

of the unbroken material, is easy to grip and handle, and is tolerant of

alignment errors. With the addition of one actuator, the joint can

be made reversible to aid in product unfolding (Section 5.1.5).

Section

3.2.2 describes a variety of press-fit connections

for conveying power, signal, and fluid between nanoblocks.

The fabricator used in the nanofactory is unspecified; the nanofactory

design is sufficiently general that a wide variety of possible fabricator

designs can be incorporated. The reader may find it helpful to study

Merkle's "assembler" (1999) (Appendix B) as a prototype.

The only requirements are that the fabricator must be capable of producing

a variety of products of size and complexity equal to itself from soluble

feedstock molecules, and that it use digital deterministic control, which

implies that the mechanochemical processes must be highly reliable.

Since only a few reactions will be sufficient to make a wide variety of

molecular shapes, and since error detection and correction will be difficult

if not impossible in early broadcast-architecture assemblers, these requirements

do not greatly reduce the generality of the present design. (Unreliable

operations can be retried multiple times even in a deterministic system;

see for example Drexler, 1992, sec. 13.3.1c).

3.1. A Thermodynamically Efficient Stepping Drive

Figure 1: Pin Drive

A mechanical device driven by a sequence of simple digital commands will

have an internal state that changes with each command, and must be maintained

without error or slippage. Thermal noise injects constant vibration

into the system, requiring strong latching mechanisms. A simple latching

mechanism is a ratchet with a strong spring, as proposed by Drexler and

used by Merkle. A stepping drive can be built from two ratchets,

and early assembler designs that are controlled by simple external signals

may make extensive use of such drives. Such a mechanism is extremely

inefficient, since the energy used to compress the spring (at least 100

kT [Boltzmann's constant times ambient temperature] to overpower room-temperature

thermal noise) is lost each time the ratchet moves to the next tooth.

However, when a fabricator is connected to a digital logic system, the

fabricator no longer needs internal state-maintenance mechanisms, and the

device can be made far more efficient. (Digital logic, including

gates and registers, can be made thermodynamically efficient.)

An efficient drive with functional characteristics similar to the ratchet

drive is the pin drive. (See Figure 1.)

In this design, pins are inserted into equally spaced holes (or notches)

in the moving bar to assure its position at all times. The latching

pin moves in and out but not sideways, and is used to hold the bar still.

The driving pin moves in and out, and also is moved sideways by a bar actuator

over a distance equal to the spacing of the holes. The pins are similar

in structure and function to the rods in Drexler's rod logic design.

To move the bar one step, the bar actuator is moved to one end of its range,

pulling the driving pin into alignment with a hole. The driving pin

is inserted. The latching pin is withdrawn. Then the bar actuator

is moved to the other end of its range, bringing the next hole into alignment

with the latching pin, which is then inserted. Finally, the driving

pin is withdrawn and then moved back to its original position. Smaller

step sizes may be obtained by additional offset pins, or by a second vernier

drive, similar to the vernier ratchet drive described by Drexler (1992,

sec. 16.3.2), with slightly different hole spacing and bar actuator range

of motion from the main drive. Larger step sizes may be obtained

by moving the bar actuator a larger distance in each cycle.

Although the pin drive requires one more actuator than the ratchet drive--two

pins and a bar actuator, instead of two ratchet pawl pullers--it has the

advantage that it can move by measured steps in either direction, whereas

the two-ratchet drive can only move stepwise in one direction and must

retract in a single motion by lifting both ratchets. (If both pins

are lifted simultaneously, the bar can be moved without restriction by

a weak return actuator, allowing the same rapid return motion as the ratchet

drive. Note that without careful design, verifying the complete return

of the bar will require energy on the order of 100 kT.) Similar redesign

can be applied to any stepping drive mechanism. As long as the position

of the moving member is initially known, it can be moved stepwise, held

stiffly against thermal noise at every point, and locked in place in its

new position, all without irreversible state transitions.

While the pins are moving, the bar is stationary and the pins may be

moved reversibly. As the bar actuator is moved, the force encountered

may vary. Nevertheless, stiffly imposed motion will be efficient

in most cases. As long as the force profile of the motion does not

vary more rapidly per distance than the stiffness of the drive mechanism,

and does not vary substantially between forward and backward motion (e.g.

due to an irreversible state transition), it does not matter how much force

is required to move the bar at each point because the energy will be recovered

when the motion is reversed. This energy recovery requirement implies

that the drive mechanism must be able to recover energy from being driven

by the bar; such designs are not difficult, and include Drexler's electrostatic

motor/generator (1992, sec. 11.7). The same argument applies to other

types of actuators driven by other digital control mechanisms: as long

as the force profile is reversible and is less steep than the stiffness

of the drive mechanism, the energy that is put into the system is recoverable.

Note that rapid motion causes the force profile to deviate from reversibility

due to various energy dissipation mechanisms. (The author thanks

Eric Drexler for clarifying discussion of thermodynamic reversibility.)

3.2. Joining Product Blocks

There are several possible ways to join two mechanochemically fabricated

objects. Van der Waals force is an attractive force that develops

between any two nearby objects. For a few unterminated surfaces,

covalent chemical bond formation can in theory be used to make a seamless

joint. A wide variety of mechanical joints can be used. Section

3.2.1

describes a particularly useful strong mechanical joint, and Section 3.2.2

describes several press-fit joints for power, control, and fluid connections

between blocks.

At very small separations, two objects experience an attractive force

called van der Waals force: simply bring them close together, and they

stick. For two flat diamond surfaces, the force is approximately

1 nanonewton per square nanometer, or 10,000 atm of pressure (Freitas,

1999, sec. 9.3.2).

This is reasonably high, although it provides only a fraction of the strength

and stiffness of chemical bonds. The van der Waals force is the simplest

method of joining, it is reversible, and it should provide sufficient strength

to keep even kg-scale products from falling apart under their own weight.

This type of joint is convenient and can be used for weak joining of structures

that must later be separated.

A diamond surface that is not passivated with an outer layer of hydrogen

will be very reactive. Unterminated diamondoid surfaces forced together

should form covalent bonds. According to Drexler, two (110) surfaces

of tetrahedral diamond or two (100) surfaces of hexagonal diamond should

bond to each other on contact, forming a seamless joint (Drexler, 1992,

secs. 8.6, 9.7.3, and 14.2.1). Sinnott et al. (1997) report the results

of simulations that show bond formation, though not seamless joining.

For other diamond surfaces, or in the case of too-rapid joining, a somewhat

weaker joint may form with a lower bond density. Also, it is currently

unknown how much pressure would be required to initiate the process.

Crushing buckyballs to diamond requires 20 GPa, but Drexler states (personal

communication, January 24, 2003) that a covalent joint should "zipper"

itself if started at an edge or corner, that neon atoms should be able

to escape the closing gap and would not interfere with the joining, and

that argon is even better in this regard. If the joint were comparable

in structure to amorphous diamond currently made for MEMS, it would have

a tensile strength of only 8 GPa (Sullivan, 2002); this is significantly

less than diamond's tensile strength of 60 GPa (measured) to over 100 GPa

(calculated, depending on crystal orientation) (Telling et al., 2000).

An additional problem is that radiation damage or stray molecules may cause

local surface reconstruction or contamination that may hold surfaces apart

and prevent a joint from forming. This type of joint is usually not

reversible, though in theory a carefully designed edge might allow predictable

crack formation. Since seamless covalent joints have not yet been

demonstrated, the present nanofactory design does not use this method.

3.2.1. The Expanding Ridge Joint

Figure 2: Expanding Ridge Joint

Each mating block face is covered with small "ridges" that are roughly

triangular in cross section. See Figure 2.

All exposed surfaces are non-reactive (e.g. hydrogen-passivated diamond).

The ridges on each face interlock with the ridges on the opposing face.

As the joint is pressed together, the ridges split and expand sideways.

The exposed surfaces of the ridges are not smooth, but are shaped to grip

the opposing ridge, with scallops deep enough to form overhangs when viewed

perpendicular to the block face. A scallop is chosen instead of a

sawtooth or ratchet profile in order to avoid crack formation at sharp

concave angles. Scallops also make assembly motions smoother, and

allow the un-powered assembly described below. The expansion of the

ridge opens a space in its center, which is then filled by a shim which

sits above the almost-closed gap between the two halves of the ridge.

Once the shim is in place, the volume of the joint cannot easily be compressed,

and the surfaces of the ridges cannot easily slide past each other; pulling

apart the joint would require compressing a solid mass of diamond by several

percent or breaking at least half of the ridges simultaneously. If

the ridges all run in the same direction, the joint may be able to slide

freely. Crossed ridges will produce a joint that is quite stiff against

shear.

The triangular shape of the ridges has several advantages. First,

the area of the base of the triangles (almost the entire area of the block

surface) is structurally solid. (By contrast, a square ridge would

waste at least half of the structural strength of the blocks being joined,

because the block area adjacent to the tops of the ridges would not contribute

to the joint.) Second, at small scales, van der Waals forces make

handling of components difficult because the components stick to any manipulator.

With triangular ridges and narrow ridge tops, the contact area of the surface

is much lower, reducing the van der Waals force. Third, a manipulator

can easily be aligned with the ridges. Small blocks can be picked

up by simple contact with a V-channeled manipulator that presents sufficient

surface area to form a van der Waals bond of the desired strength, and

the manipulator will automatically be pulled into alignment. A more

complex mating pattern could fasten on several ridges at once. If

the ridges are placed at varying angles or spacings, a well designed manipulator/ridge

interface can guarantee that a misaligned manipulator cannot form a firm

grip. Likewise, a well designed ridge/ridge interface can guarantee

that misaligned blocks will not join incorrectly.

There are at least three ways of mounting the ridge so that a small

attractive force between mating ridges will be sufficient to cause the

ridge to spread. The first possibility is to join the ridge to the

nanoblock with dovetail joints, permitting it to slide sideways with very

low friction. A simple dovetail joint costs somewhat more than half

of the possible joint strength; a stairstepped dovetail joint (which is

similar to a completed ridge joint) would recover much of the strength

at the cost of additional volume and complexity. The second possibility

is to use a mounting that is strong in tension but flexible in shear, such

as thin columns of diamond or buckytubes. The third possibility,

for use in linear stacks of many nanoblocks, is to build a solid structure

extending from the base of the ridge all the way through the block to the

ridge on the opposing face. Both ridges would move in tandem, and

be locked in place when the shims were dropped on each side. This

might require a mechanism for retaining all participating shims until all

joints are pressed together.

The simplest version of the expanding ridge joint requires no actuation

to form the joint other than moving the faces together. As the faces

are brought together, just before the final closure, each row of scallops

brushes past the inverse row on the opposing ridge. As the interlocking

ridges from each surface interpenetrate, the bulges of the scallops brush

past each other, close enough to be attracted by van der Waals force.

This pulls the halves of the ridge apart. The attraction between

passing scallops when the faces nearly touch must be stronger than the

intra-ridge attraction, to ensure ridge spreading during the last phase

of joint insertion, as the final rows of scallops pass each other.

This is ensured by the use of small spacers to control the van der Waals

force holding the intra-ridge gap closed. (The spreading will become

increasingly favorable as the faces approach, and the operation will happen

slowly enough to allow equilibration, so thermal noise will not cause the

joint to fail to close.) However, the intra-ridge attraction (between

halves of the same ridge) must be strong enough in the initial position

to prevent premature operation due to thermal noise. The half-ridges

must require a certain energy, say 100 kT, to pull them apart far enough

for the shim to be inserted; the displacement which absorbs this energy

cannot be greater than the depth of the scallop. Note that the required

energy is not dependent on any spatial parameter; it is related only to

temperature. However, the attractive force is approximately proportional

to surface area, so this condition can be satisfied by a sufficiently long

ridge joint. In other words, regardless of the actual inter-scallop

force, an intra-ridge gap can be chosen that will allow the ridge halves

to be separated; and regardless of the gap, a sufficiently long ridge will

be resistant to premature separation.

Due to the complicated geometry of the scallops, exact calculation of

the attractive force between mating ridge halves is beyond the scope of

this paper. An inaccurate calculation is given to permit crude estimation

of minimum ridge length. The formula for attraction between cylinders

(Drexler, 1992, Fig. 3.10f) will be applied, treating each scallop as a

0.5-nm radius cylinder separated by 0.3 nm. (This is inaccurate because

it ignores the attractive contribution from the material behind the cylinders,

and because the formula's derivation assumes that cylinder radius is much

greater than cylinder separation.) The inter-scallop potential energy

is calculated as 61 zJ per linear nanometer of scallop contact, which corresponds

to 2 nm^2 of surface between the two halves of the ridge. To reduce

the intra-ridge potential energy to 50 zJ per scallop-nm or 25 zJ per nm^2,

the spacing must be at least 0.6 nm (ignoring the attractive contribution

from the spacer) according to the formula in (Drexler, 1992, Fig. 3.10d)

which slightly overestimates the attractive force since the ridge is not

infinitely thick.

When the gap between the half-ridges is fully open, the shim (which

includes a hollow to accommodate the spacer) is pulled into the gap and

held there reliably by van der Waals force. The shim will insert

when the ridges have moved apart by a distance equal to the depth of the

scallop undercut, in this example 1 nm. With a 1-nm deep scallop

and a 0.6 nm initial gap (thus a 1.6-nm wide shim), the difference in potential

energy between 0.6 nm and 1.6 nm spacing is 21.5 zJ/nm^2. To prevent

premature insertion, the intra-ridge potential energy of attraction must

differ by 100 kT (260 zJ at 0 C) between closed and open positions.

This requires 12 nm^2 of intra-ridge gap. If the ridge is 8 nm high

(with 4 scallops), then it need only be 1.5 nm long.

The joint may be stiffened by compressing the joint volume. In

this case, extra force may be used to insert the shim into the gap.

(This also allows the gap to be somewhat narrower, reducing non-structural

volume.) A simple design for an electrostatic actuator adds only

one moving part. The shim is blanketed between insulated capacitor

plates, one of which is flexible. Charging the capacitor makes the

plates pull together, expelling the shim like a watermelon seed.

The electricity to power the actuator can be delivered through contact

with small embedded conductors at the proper time during the convergent

assembly process. The tip of the shim can be tapered to help spread

the ridge halves. Once the shim is expelled, the capacitor plates

will adhere to each other by van der Waals force, forming a reliable barrier

to hold the shim in the joint even if the capacitor is discharged.

Tension on the joint will tend to expand the entire joint volume sideways.

This can be constrained by surrounding each joint (not each ridge) with

a diamond collar sufficient to resist the sideways force generated by a

single ridge. The ridge joint is somewhat less stiff in tension or

compression than solid diamond would be, but should be almost as strong:

failure requires either significant compression of a large volume of diamond,

or the simultaneous failure of many covalent bonds. Effectively,

the entire joint volume except for the depth of the scallops and the width

of the shim contributes to the tensile strength, and the entire joint volume

except for the shim contributes to the compressive strength. Shear

strength and stiffness depend on the orientation and attachment of the

ridges, but can be made quite high perpendicular to the ridge line.

Torsional and bending strength and stiffness can also be made quite high.

The width of the shim is unrelated to the size of the ridge, being equal

to the depth of the scallop's undercut plus the intra-ridge van der Waals

gap. A reasonable lower bound for component size is a ridge composed

of four scallops 1 nm deep and offset by 1/2 nm horizontally and 2 nm vertically.

The height of the ridge is 8 nm, and the footprint of a half-ridge is 3.5

nm (accommodating 0.5 nm of motion to mate with the opposing half-ridge),

of which 2 nm contributes structural strength. The 1.6-nm wide shim

adds an additional 0.8 nm of non-structural overhead to each half-ridge;

the total joint tensile strength is approximately 47% of solid diamond.

(Shallower scallops will improve this number up to a point; scallops that

are too shallow can fail by slipping past each other.) For reliable

operation the ridge must be at least 1.5 nm long. The smallest joint

consists of one half-ridge on each side, only one of which (and its shim)

needs to move; the rest of the joint including the mating half-ridge can

be solid diamond. A single joint can potentially have a footprint

smaller than 3x6 nm. Larger ridges can have more scallops, with the

size of each scallop (and thus of the shim) staying constant. For

example, a half-ridge 20 nm high with 10 scallops has a footprint of 6.5

nm (plus 0.8 nm for its share of the shim) of which 5 nm is structural,

for 68% of diamond strength. Covering a 200-nm block with 8-nm-high

ridges on each side requires 8% of the block volume (ignoring block edges

and corners). However, in a high-strength application that requires

ridge joint coverage of the full surface, the block must be nearly solid

diamond anyway.

Because the strength of the joint decreases only slightly with smaller

size (the decrease is a function of the minimum shim, scallop, and van

der Waals gap size), small ridges are mechanically adequate for joining

blocks at any scale. Minimum ridge size is determined by the mechanochemical

fabrication process. The only limitations on block size are the precision

of the block-handling machinery and the possibility of unequal expansion

of the faces due to temperature differences. With 200 nm nanoblocks,

ridges built in a single block can be up to 100 nm in height, with tops

50 nm apart. (Note that the blocks will overlap by the height of

the ridge. The change in effective block width during assembly presents

issues for the assembly process that are straightforward but beyond the

scope of this paper.) An assembly tolerance of 0.05 micron is somewhat

beyond today's standards; current state of the art for automated pick and

place assembly for optical components appears to be around 0.5 micron (Blaze

Network Products, 2003). However, today's pick and place systems

use hardware made with a manufacturing tolerance comparable to its performance.

In contrast, the dimensional precision of the nanofactory's hardware will

be approximately one atomic diameter or less, regardless of scale.

At large scales, single ridges can be assembled from multiple nanoblocks,

allowing ridge spacing of multiple microns; this is sufficient even for

today's robotics.

Differences in fabrication processes, assembly processes, and internal

structure may cause different blocks to be at different temperatures.

The resulting thermal expansion can cause a misalignment of the ridges.

The volumetric thermal expansion coefficient of diamond is 3.5x10^-6/K

(Freitas, 1999, Appendix

A); the linear coefficient is one-third that, or 1.2x10^-6/K.

A temperature difference of 1 K thus causes a 200 nm block to expand by

a small fraction of an angstrom, while a 10.5-cm surface will expand by

126 nm. Because diamond is an excellent conductor of heat, passive

equilibration may be sufficient. As long as the displacement is not

greater than the ridge spacing, or the ridge pattern does not permit improper

joining, the blocks may be pressed together slowly, allowing the temperature

to equalize. Even a rarefied internal atmosphere will also facilitate

temperature equalization between nearby faces, though this process may

be slow depending on block mass, and the process will be somewhat slower

with argon than with neon. Note that the nanofactory is cooled by

phase transition (see Section 8.2), so the cooling

fluid will have the same temperature throughout the factory, minimizing

potential product temperature differences. Active compensation might

involve sensing the temperature at various points on the surfaces and applying

heat to the cooler surface via embedded resistive heaters; this will only

be necessary for the few large-scale joints that take place near the end

of the assembly process, and the heating process can be initiated in advance

to avoid delay. Embedded mechanical (bi-material) thermostats can

allow each region to reach a preset temperature without individual attention.

Because the joints require no external manipulation or assembly force,

they can be used to fasten non-bonded parts that are only loosely connected

to the main nanoblock. For example, a structural beam one micron

long and 50 nm wide can be constructed in five sections. Each section

will be terminated in ridge joints, and laid across a nanoblock in a position

that will place the section ends next to each other during block assembly;

van der Waals force will hold the section in place during block manipulation.

When the nanoblocks are assembled, the ridge joints of the beam will join

at the same time as the rest of the joints, with no additional effort.

This allows the inclusion of long, thin components in product designs.

Likewise, single nanoblocks can be made in separate pieces joined by van

der Waals force. This allows a block to be pulled apart during the

unfolding process, forming multiple walls with large spaces between them.

This can be useful to save mass where only thin walls are needed.

If a block is split into as many as 10 walls or 100 columns, the 20-nm

width is sufficient for multiple full-sized ridge joints on each part.

This capability is assumed for interior nanofactory structure.

Joints can be formed after the product is released from the factory,

as long as contaminants have been excluded from the joint space.

The factory can manufacture a larger containing balloon for product unfolding,

or the joints can be protected individually by a variety of covering mechanisms.

A product can be created in a very compact form, then unfold like a pop-up

book or like flat-packed cardboard boxes. Components can be built

in pieces, with lightweight pantographic trusswork to bring the ends together

as the product expands; once the ends touch, the strong joint will form.

A component can also be made in a "broken" state, with mating surfaces

held together on one edge with a small hinge at any desired angle, and

the open end protected by a bellows if necessary. When the component

is straightened, the mating surfaces will form the desired strong connection.

A weak and reversible joint can be formed by preventing the shims from

entering the gaps between the ridges. This allows blocks to be loosely

connected, then disconnected, and finally reconnected tightly in the same

or different configuration. This may be useful if the unfolding process

requires a structure to be produced in its final conformation, then flexed,

and finally fastened rigidly.

3.2.2. Functional joints

A product may contain embedded wires, pipes, rotating rods, nanocomputer

logic rods, and polyyne control cables. All of these may need to

make a connection between adjacent nanoblocks. These connections

are generally simple, and cost less than 50% of the performance that would

be possible with a seamless design.

Embedded wires can be run up to a flat face, and electrical contact

made by tunneling. Contact can be maintained in the case of joint

strain by the use of springy interfaces. According to measured values

for a sample of HOPG (highly ordered pyrolitic graphite), (GE Advanced

Ceramics, 2002) graphite is about 5000 times more conductive in-plane than

cross-plane (and the in-plane value is 1/50 as good as a typical metal).

The separation of graphite planes is 0.335 nm, about 1/600 of the 200-nm

nanoblock width. This implies that a graphite-graphite tunneling

surface of 8 nm^2 per nm^2 of graphite wire, spaced every 200 nm, would

only double the total resistance. To save nanoblock surface area,

the tunneling surface can consist of interlocking corrugations. Because

diamond is an excellent insulator, high voltages may be used to compensate

for the resistance of graphite. Some buckytubes may be better conductors.

Control cables and control rods will be built into each nanoblock when

it is manufactured, and extend only to its edges. Tension and/or

compression must be transferred between blocks. Nanocomputer logic

rods have ends ~1 nm^2 which can be butted together. The nanocomputer

design uses tensional force of 2 nN (Drexler, 1992, sec. 12.3.3.b) but

this can be traded for displacement or compressive force without sacrificing

reliability. Alternatively, the joint area can be increased by a

few nm^2 to allow a few nN of tensile force to be transmitted through van

der Waals attraction. Crossing between blocks may require adding

extra logic gates to transform and condition the signal; this logic can

all be reversible at some cost of time. Such interfaces will not

add significantly to the power requirements or design complexity of a nanocomputer.

Polyyne (carbon chains with alternating single and triple bonds) control

cables can be terminated with a small diamondoid plate flush with the nanoblock

surface. When the blocks are joined, the plates will stick by van

der Waals force. Each two atoms of polyyne spans a length of 0.2569

nm and has a compliance of 0.00185 m/N (Casing an Assembler, "Control cables").

A 1-nm diamond cube contains 176 carbon atoms. A van der Waals interface

has a stiffness of >30 N/m per nm^2 (Drexler, 1992, sec. 9.7.1), or a compliance

of <0.0334 m/N. Two hundred nm of polyyne contains 1557 carbon

atoms and has a compliance of 1.44 m/N, while 198 nm of polyyne interrupted

by two 1-nm diamond cubes interfaced by van der Waals force contains 1893

carbon atoms and has a compliance of 1.47 m/N; the interface increases

cable mass by 22% and compliance by 2% (ignoring the hydrogen termination

and internal compliance of the diamond cubes) and may introduce resonances

into extremely high-speed operations. The main drawback of the interface

is its strength; the tensile strength of a polyyne rod is >6 nN, but the

strength of the interface is ~1 nN. Increasing the interface area

allows a stronger and stiffer joint, and for joint areas above a few square

nanometers a ridge joint can be used at some cost of mass.

Power can be transmitted by means of thin rotating rods, embedded in

the nanoblocks like the control cables and logic rods. Mating convolutions

on rod ends will allow the transmission of torque between ends that are

simply pressed together. If the rod is driven near maximum torque,

the interface may need to be somewhat larger than the cross section of

the rod. The bursting speed of a disc decreases in proportion with

its radius, while the area increases as the square of the radius; thus

a 2x increase in interface area will cause a 1.4x reduction in speed.

In this simple example, power transmission is derated by 40%; however,

other mechanical linkages such as a thin belt connecting offset and overlapping

rods may permit full speed while delivering full torque. (The belt

can be placed around one rod during nanoblock manufacture and held open

by any of a variety of methods. The other rod can be tapered to slip

inside the belt during block assembly. Interlocking (gear-toothed)

rod surfaces will also work but may require significant overlap for reliable

torque transmission.) Rods and shafts larger than a few nm can be

joined by ridge joints. Ridge joints may also serve as a means of

chocking the shafts to ensure proper alignment, and then unlocking them

during convergent assembly: the shims can be inserted only when the joint

is fully closed, and the motion of their insertion can be used to remove

a mechanical chock. Small rods can be controlled by adjacent ridge

joints, and large shafts by facial joints with internal shims.

Bearing surfaces for rotating shafts small enough to be embedded in

nanoblocks can be built into each nanoblock during construction.

Variations in rod diameter will prevent the rods slipping out of the block

prior to convergent assembly. Large rods pose a special problem for

convergent assembly, since they cannot be strongly and permanently fastened

to a support or bearing structure. However, for products up to 10

cm size, a tight-fitting bearing surface between a rod and a housing can

provide the necessary adhesion by van der Waals force alone. Rotational

freedom can be constrained by small retractable chocks. Graphite

pads covering the matching surfaces of the blocks constituting the shaft

and the blocks constituting the housing can provide a bearing surface even

for slightly rough curved surfaces. However, the boundaries between

the pads will be aligned on the moving and bearing surface, and this can

create a significant force. (Twisting one of the surfaces relative

to the other would break the alignment, but this will not be possible for

cylindrical bearings.) Order-of-magnitude calculations can be made

by treating the boundary gaps as regions of wider spacing between the surfaces,

calculating the difference in van der Waals energy between aligned and

unaligned regions, and dividing that by the width of the gap to find a

force. Approximating the boundary as a trench 1 nm wide and 0.1 nm

deep and the pad spacing as 0.2 nm, and applying the formula from (Drexler,

1992, Fig. 3.10d), indicates an energy difference of 81 zJ per nm^2 in

favor of the aligned state, or an average force of 81 pN per linear nm

of trench. One mm^2 of flat sliding surface will contain 5x10^9 nm

of trench crossing the direction of motion, creating a force of ~0.4 N.

However, the stiffness of 1 mm^2 of graphite bearing surface is ~3x10^13

N/m, so for many macroscopic applications, bearings may be made small enough

that the "roughness" is not a significant problem. A cylindrical

bearing surface cuts across two nanoblock planes and only a fraction of

the area contributes to stiffness; these factors increase the number of

trenches (and thus the "roughness" force) for a given bearing stiffness

by approximately a factor of 4.

Pipes are simply voids in the diamond nanoblocks that are butted together

when the blocks are assembled. A flat, uncompressed interface between

nitrogen-terminated diamond (111) surfaces is adequate to exclude helium

(Drexler, 1992, sec. 11.4.2a). If this type of interface proves inadequate

in practice (perhaps due to joint flexure, or unavailability of nitrogen

termination chemistry), a conical extension of the pipe wall wrapped in

one or more layers of graphite to provide a compressive seal and extending

into a conical depression in the other block should suffice. Pipes

too large to be contained inside a nanoblock can be sealed by diamond or

graphite curtain walls, placed along each seam, to separate the interior

of the pipe from the mechanical joint area. If the nanofactory is

filled with inert gas, pipes will also be filled with the gas when they

are manufactured. If this is a problem, one possible solution is

to place a collapsed graphite tube inside the pipe, terminating the tube

ends at the nanoblock faces with a diamond mating collar thin enough to

be flexible. When the blocks are assembled, the collars join.

When first used, the graphite tube will expand and conform to the walls

of the pipe while displaced gas can be vented through small channels.

4. Nanofactory Architecture

A nanofactory, as conceived here, is a single device containing many mechanochemical

fabricators and larger-scale manipulator systems. The mechanochemical

fabricators produce nanoblocks and the manipulator systems join them into

a product. The mechanochemical working space of a nanofactory must

contain no stray reactive molecules. The factory must contain computers

to control the machinery; space and mechanisms for convergent assembly;

structures for distributing power, chemicals, and cooling fluid; mechanochemical

fabricators with space for them to work; and additional space for joining

blocks into larger blocks and transporting them through the factory.

The nanofactory is built hierarchically, using only a few scalable designs.

At the lowest level, a few thousand fabricators are arranged in a planar

grid. Their products are picked up and assembled into increasingly

large blocks by a series of increasingly large robotic manipulators.

This plus a control computer constitutes a basic, reliable production

module. The production modules are stacked three-dimensionally

into gathering stages, which assemble blocks and pass them to higher-level

gathering stages. Finally, the entire factory is enclosed in a suitable

casing, with a mechanism to output product without contaminating the workspace.

In Merkle's convergent assembly architecture (1999) it is suggested

that each convergent assembly stage has four inputs, each supplying two

blocks to make one output block. However, this means that each input

to the preceding stage must supply four blocks to make those two, and so

on. This is feasible if blocks can be manufactured extremely quickly,

or (as in Merkle's design) fed through a relatively small number of ports

efficiently. The current design, using large nanoblocks requiring

minutes or hours to fabricate, uses only one block from each fabricator

per product cycle. This implies that each stage will receive all

its blocks in parallel. In general, then, each stage must have either

eight (non-redundant) or nine or ten (redundant) inputs. (The first

gathering stage has only four inputs, to compensate for the eighteen inputs

of the final stage in the production module; see below.)

4.1. Mechanochemical functionality

Figure 3: Workstation Grids

Once a self-contained, digitally controlled mechanochemical fabrication

system has been developed, the fabricator design can be copied directly

from it. Early systems will presumably use a simple, stiff robot,

such as a double tripod (Merkle, 1997c) or Stewart platform. As noted

in Section 8.2, any inefficient ratchet or other state-keeping

systems in the fabricator can be replaced with thermodynamically efficient

stepping drives. Even with this improvement, the primitive method

of mechanochemistry will cost some efficiency relative to the "mill" type

designs analyzed by Drexler (1992, sec. 13.3) and used in his nanofactory

design (1992, sec. 14.4). Because placing each atom or molecule requires

a large and complicated motion of the tripod system, the nanofactory will

suffer some penalty in both speed and energy use; these penalties are substantial

but not crippling. Mills are not included in this preliminary design

because they may require significant additional mechanical and mechanochemical

design.

Fabricators will be fastened together edgewise to form the planar array,

which divides the coolant volume from the working volume. Cooling

fluid with dissolved feedstock circulates past one side; the products (nanoblocks)

are fabricated and released on the opposite side, which is open to the

nanofactory's clean working volume. A square of nine fabricators

(one redundant) forms a stage. Product blocks are picked up by a

three degree of freedom gantry crane manipulator and assembled into a 0.4-micron

block. Likewise, a square of nine of these stages forms the next

stage. This continues through several levels; in the current design,

four levels is chosen for suitable redundancy and convenient control.

4.2. The reliable basic production module

Figure 4: Production Module

A production module fabricates two 3.2 micron product blocks out of up

to 8,192 nanoblocks, using a fabricator to produce each nanoblock.

The module is extremely reliable in the face of radiation damage, and is

controlled by an integrated nanocomputer. The overall shape of the

module is a rectangular solid ~16x16x12 microns. The fabricators

are placed on two opposite sides, delivering their product nanoblocks to

the interior. The nanocomputer occupies a third side, surrounding

the product exit port. The remaining three sides may be closed by

thin walls, but need not be closed at all where two production modules

are placed side by side in the nanofactory. The interior is sparsely

filled with gantry crane manipulators to assemble the nanoblocks into larger

blocks. The gantry crane mechanisms, even at the smallest scale,

can be implemented as bulk diamond machines--the smallest blocks are 200

nm on a side, and bulk diamond parts can be designed far smaller than that,

so not much material or volume will be wasted due to inefficient design

constraints. With the ridge joints, the blocks can be assembled simply

by bringing them into contact (Section 3.2.1).

Rotation of blocks will not be necessary because each block (or partial

block) can be manufactured in the same orientation it will take in the

final product (before unfolding). The design of the ridge joints

provides a rough surface that can be gripped with as much force as necessary

to accelerate the cubes and (depending on scale) overcome gravity.

The physical layout is similar in some respects to Merkle's architecture

for convergent assembly (Merkle, 1999). Substage outputs are be grouped

on one wall of an assembly chamber, forming the inputs to the stage; substages

are placed side by side, and stages are stacked on top of substages.

See Figure 4. As in Merkle's design,

the output from a stage is twice the width of each input; unlike Merkle's

design, each input port delivers only one block per product cycle instead

of two. The design is not quite scalable, since the width of the

assembly stage is three times the width of the sub-stage, while the width

of the block that is produced is only two times the input block size.

The ninth substage is redundant, used in case of failure of another substage.

Four levels of redundancy are probably sufficiently redundant for a nanofactory

of the size contemplated here. Otherwise, more redundancy can be

added in a fifth stage, or by extending a gathering stage; see Section

8.5

for calculations.

The module's top and bottom surface are completely covered with 9^4

= 81^2 = 6561 mechanochemical fabricators each. To provide space

for moving sub-blocks around a growing assembly, each stage is 3.1 times

as high as the sub-block it receives. Two of these assemblages are

sandwiched together, sharing a single 3.2-micron assembly stage, to make

one production module that produces two 3.2-micron blocks per product cycle.

The design can be compacted somewhat if multiple convergent assembly stages

can be combined; such optimization is beyond the scope of this paper.

The CPUs, memory, DMA controllers, and motors are placed on the face that

contains the output port, forming a single layer and extending the width

by 0.2 micron. Controlling a column of 81 fabricators requires perhaps

a few billion bits per second and <100 pW (Section 8.2),

which fits through an interface requiring only a few nm^2. Only 4096

fabricators per side are used at any time; the rest are redundant, to be

used in the event of radiation damage. See Section 8.5

for further discussion of this design. Powering the entire set of

8192 fabricators plus the computer requires 8 nW, far smaller than the

500 nW capacity of a single electrostatic motor.

4.3. Gathering stages

Figure 5: Convergent Assembly Fractal Stages

The production module is scaled to tabletop or larger size with a simple,

repeatable architecture. Each gathering stage fits neatly into a

rectangular solid, with the substages arranged in two rows on either side

of a central assembly and transport tube. The substages, themselves

rectangular solids (including the production module), fit together with

no wasted space in each row. Space is wasted between the rows, adjacent

to the central tube. Gaps are left for feedstock/cooling channels

adjacent to certain faces of the production modules. Wherever no

gap exists between substages, no walls are necessary. As the modules

are stacked, the cooling channels line up; the overall arrangement is a

quasi-fractal working volume interpenetrated by a non-fractal cooling channel

volume. Power and signals are routed through the walls of the transport

tubes, since the end of every transport tube touches the side of the next-larger

tube. Power can be distributed through rotating rods or conductive

graphite or buckytube inclusions (wires) in the structural diamondoid blocks.

Control signals can be sent mechanically through polyyne rods, or electrically

through wires. The current design does not require fractal distribution

of liquids, since feedstock is dissolved in the cooling fluid. Inspection

of Figure 5 shows that some coolant channels

will be blocked by assembly tubes in stages with numbers divisible by 3;

this requires a gap between the sub-stages and the tube that is a fraction

of the cooling gap width, which is not included in the present calculations.

It may be desirable to prevent fluid from flowing into large voids adjacent

to the delivery tubes, to prevent excessively slow flows that could allow

suspended particles to settle out. More detailed design is beyond

the scope of this paper.

The factory does not require a hierarchical network of computers, since

the computation is done either at the top level or at the level of individual

production modules (see Section 6). Once the blocks

are fabricated, a fraction of the production module computers can be used

to run the convergent assembly robotics. If hierarchical computers

are needed, the computers can be built into the tube walls. Amplification

will be needed to distribute the top-level signal to each of the production

modules. This can be implemented in each stage, and can be combined

with a mechanism to send a unique, hard-coded position indicator to each

production module. By knowing which branch the signal takes at each

stage, the module's computer can easily determine the position of its output

in the final product.

A tabletop factory might produce a 10.5-cm product; this is 2^15 times

larger in linear dimension than the 3.2 micron output of a production module,

so product assembly requires 14 further assembly stages where each stage

assembles 64 sub-blocks to produce eight product blocks. See Figure

5, and Section 8.3 for dimensions. A final

stage, external to the factory, is described in the next section; it assembles

eight 5.25-cm sub-blocks (per product cycle) to produce the final product.

Note that the first stage in the Figure is not an assembly stage, but serves

only to gather 8 sub-blocks for delivery to the next stage, since each

production module makes only two blocks per product cycle. Each assembly

stage gathers 64 sub-blocks from substages, assembles them within the assembly/delivery

tube, and delivers the 8 assembled blocks to the superstage. With

the current size parameters, in some of the smaller stages, a minimum-volume

arrangement leaves the tubes perhaps too short for simultaneous assembly